- Can we help you?

- +34 694290755

From exploratory studies to certified GTMS

production, VAC-TRON ensures every detail meets your mission’s demands.

In many high-tech sectors, companies know they need hermetic solutions but don’t yet have a well-defined product. In our R&D Services, we act as your innovation partner: we explore technologies, test materials, create proof-of-concept prototypes, and validate ideas. Through iterative feasibility assessment, we help you reduce risk and define clear requirements before committing to detailed design or manufacturing. The result: a roadmap, validated concept or prototype that accelerates decision-making and lowers development cost in later phases.

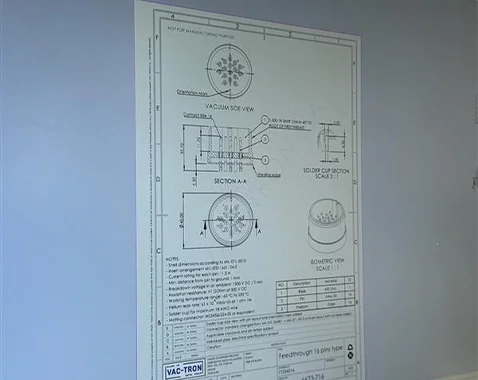

Once the concept is validated, we advance to full engineering: system-level design, thermal and mechanical simulations, electrical interface definition, and detailed drawing deliverables. We work closely with your team to ensure compatibility with your requirements—whether for aerospace, oil & gas, nuclear or scientific instrumentation. The result: manufacturable and optimized designs that balance performance, reliability, cost and compliance.

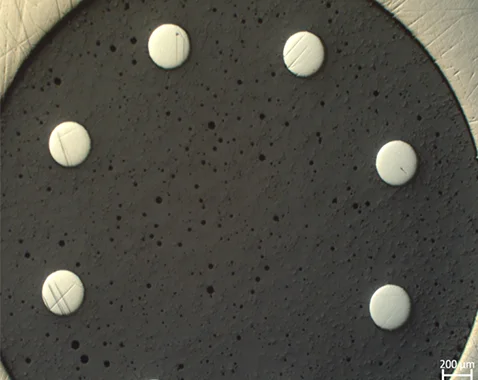

With engineered designs in hand, we produce your glass-to-metal sealed parts with precision and control. Our facilities allow for the fabrication of robust GTMS components able to withstand extreme temperatures, pressures, and vacuum conditions. We adapt processes to your specifications—pin count, geometry, materials—while ensuring reproducibility and scalability. You receive components ready for integration, with low defect rates and consistency.

To enhance performance, longevity, and compatibility, we apply in-house surface treatments, including nickel, gold, and tin plating or other coatings. Our treatments are optimized to adhere over GTMS joints, maintain conductivity, resist corrosion and meet environmental demands. These coatings extend the lifetime of your device and allow it to operate reliably in harsh environments.

Quality at VAC-TRON is twofold: first, we adhere to management systems (EN 9100, ISO 9001, ISO 14001) to ensure that every step is traceable, auditable and governed by a structured process. Then, each component undergoes rigorous technical inspections (MIL-STD standards, JEDEC protocols or customer-specific criteria). The result: you receive parts validated not only under generic standards but custom-tested to your project’s requirements.

Not every project requires ultra-clean handling, so we adapt packaging and inspection to your needs. As standard, components are cleaned and supplied in custom protective packaging to ensure they arrive in perfect condition. When required—for applications such as UHV, or nuclear environments—we offer final cleaning, inspection, and packaging inside our ISO 7 / ISO 8 certified cleanroom. This flexibility allows you to choose the right level of contamination control for each project.

“The components meet our expectations. I appreciate that only via email and no Zoom meetings we received the desired result. We will further evaluate the connectors with integration/welding into a feedthrough assembly

Mechanical Engineer - Rapid Division